The seagrass Posidonia Oceanica forms some of the oldest and largest living colonies in the world. It is a vital component of Mediterranean oceanic ecosystems, with marine biologists dating some coastal meadows to 2000 or even 3000 years old.

In Greece and all across the Mediterranean, hundreds of tons of Posidonia leaves wash up on the shore every year, causing a headache for local authorities. The leaves require public spending to collect and are disposed of in landfills as waste.

But they are a natural resource and Greek entrepreneur Stavros Tsompanidis has made it his mission to see their potential realised. He sat down recently with 4i-mag to discuss his vision and his passion for bringing the circular economy forward through upcycled materials.

Giving leaves new life

Originally a student of finance, the young founder has made it his calling to put Mediterranean nature centre-stage in people’s everyday lives. Stavros and his impact start-up PHEE developed and patented a process for upcycling dead Posidonia leaves, creating the world’s first biobased composite material reinforced with Posidonia fibres.

PHEE-board finds commercial applications in a range of products and accessories, with a potential foray into the construction industry marked for the near future.

Through a striking range of sustainable products and circular business practices, PHEE is cultivating awareness about the need to reduce the use of fossil fuel-based conventional materials and increase access to green alternatives.

The company’s manufacturing technology makes this all possible.

“The technology transforms the seagrass leaves into a new, bio-based composite material called PHEE-board, which is produced in rigid panel sheets,” Stavros explains.

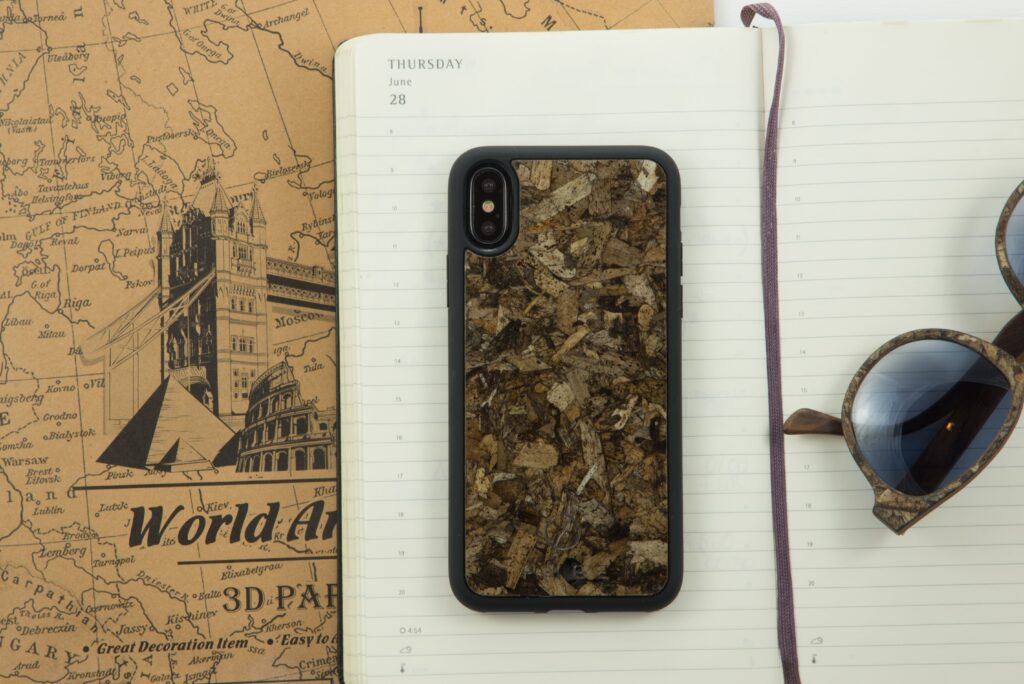

PHEE-board is lightweight, water-resistant, and always distinctively patterned — meaning that every application and every end product is unique, the founder explains.

The material uses certified bio-based resins for binding and is already being used in a number of collaborations with end product manufacturers, from packaging and mobile phone cases, to sports equipment and sunglasses.

PHEE is working with chemical specialists to test different bio-based resin systems in order to improve and increase the bio-based content in the final material.

Stavros has also set his sights on sustainable furniture, interior design materials, wall coverings, and potentially flooring — all using PHEE-board.

But the entrepreneur makes clear, this is only the beginning.

Transformative technology

There are currently no plans to grow the seagrass, given the huge quantities of leaves produced naturally each year, Stavros says.

The vision is ultimately to license PHEE’s manufacturing technology across the Mediterranean to other entrepreneurs who can then use it to upcycle Posidonia residues in their local areas, Stavros explains.

“We are not only offering new alternative materials; we are also producing them in a way that is very close to carbon neutral,” he says, adding that sustainability is a core aspect of the entire production process.

Stavros believes that the company is well positioned to take these materials quickly to market, and underlines that the manufacturing process is a key part of his company’s edge.

“The electricity consumption of our technology, as compared to others producing similar materials, is 50% lower,” the entrepreneur explains, adding that this is obviously very important for the industry.

The technology also produces minimal waste and is very nearly carbon neutral, Stavros says — “We don’t use carbon at any stage of our production.”

PHEE is preparing a lifecycle sustainability assessment which will be made public in the near future.

Scaling up sustainability

“Our business model is really simple: we are the raw material manufacturers and providers, and we are doing collaborations with other brands who are transforming them into other end products,” Stavros says.

The entrepreneur believes that this approach lends itself to a rapid scaling up process, allowing PHEE to impact a greater number of people and businesses.

What is essential, he says, is to foster greater awareness of circular economic practices with the company’s partners, building not just one impact start-up, but an ecosystem that thinks sustainability first.

“It’s very important to cultivate them, educate them in how to switch to more sustainable raw materials in their value chains,” Stavros explains.

The scale of the founder’s ambitions is clear to see: two further applications for the technology will be rolled out shortly.

The soon-to-be-commercialised raw materials will use the same concept of upcycling and transforming waste into a useful product as PHEE, Stavros explains. In September, the entrepreneur aims to launch a new parent company, which will oversee PHEE and the commercialisation of the other two brands.

“Our concept in developing these new materials is to transform the biowaste of an industry into a product that can be used again in their value chain,” Stavros explains, adding that he sees this as the best market strategy for upcycled products in general.

Biowaste materials on the table for Stavros include spent coffee grounds and tea residues.

The current trajectory of the company revolves around scaling up production capacity, developing and growing the team, and automating manufacturing processes, Stavros explains. Commercially, PHEE will continue collaborating closely with external brands for the creation of end products over the next 1 or 2 years.

To make this all possible, Stavros aims to finalise a seed round of fundraising by the end of 2021.

Up to now, PHEE has been funded through grants, fellowship awards, and founder investment. At present, the team is five people with one operating facility in the city of Patras in Greece.

Stavros Tsompanidis was nominated for the Forbes 30U30 Europe 2018 Industry & Manufacturing list, highlighting the best up-and-coming material and manufacturing innovators in Europe.