Agricultural waste upscaled

Have you ever wondered what rice husks may be used for? We never or rarely do. Rice husk is a brilliant byproduct of milling rice and is used as a building material, fertilizer, insulation, or fuel. Moreover, burning rice hulls produces rice hull ash, a potential source of amorphous reactive silica. It is used to make Portland cement because ash is an excellent thermal insulator.

Still, globally, a significant amount – 100 million tons – of rice husk is disposed of as waste. However, since we live in a world of accelerated technological development and innovations and the concept of the circular economy, which we will cover in-depth in some of our articles, later on, is rapidly catching on, waste disposal will no longer have to be disposed of being the solution. Hence, scientists are constantly trying to find ways to reuse every byproduct and waste material, including those from the agriculture sector.

Pillars of a sustainable bioeconomy

A sustainable bioeconomy requires that the byproducts and byproduct streams of agricultural and food production be returned to the value cycle, a concept also known as recovery or recycling. The concept is an important innovative practice aimed at sustainable development, contributing to waste reduction and efficient use of resources.

For example, organic waste from agriculture has long been used as fertilizer. Organic wastes such as stalks, leaves, and legumes of crops, as well as animal wastes, can be converted into fertilizers rich in nitrogen, phosphorus, potassium, and other nutrients, which are very cost-efficient. Therefore, many agricultural byproducts and waste materials can be reused and utilized. However, the recent discovery by a research group at Hiroshima University may change technology forever.

The journey from milling rice to LED lights

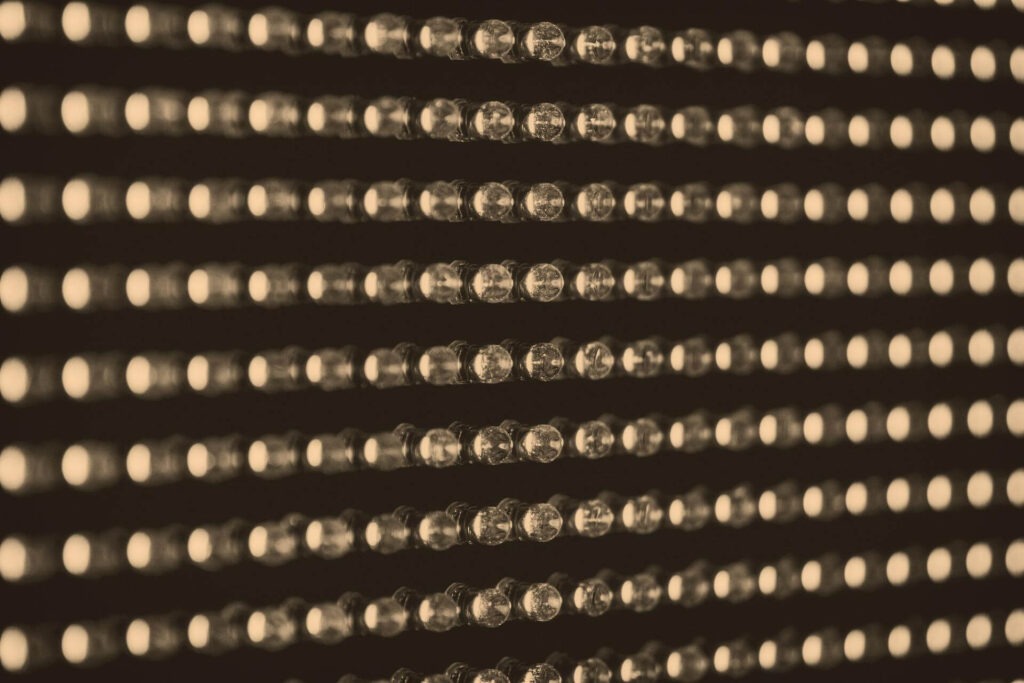

Recently, a group of scientists at Hiroshima University searching for a scalable method to fabricate quantum dots published their findings and innovative solution to creating the first silicon quantum dot (QD) LED light. What is extraordinary about this innovation is that it might eliminate toxic materials from producing QD in the long run and benefit the environment and human health.

The new method transforms agricultural waste into state-of-the-art LED (light-emitting diodes) cost-effectively and environmentally friendly.

The findings of the research team from the Natural Science Center for Basic Research and Development at Hiroshima University were published this year in the American Chemical Society journal ACS Sustainable Chemistry & Engineering.

What are quantum dots?

Quantum dots (QD) are semiconductors that are considered ideal light emitters for displays. From TVs and solar cells to cutting-edge cancer treatments, quantum dots have considerable potential in many fields. But manufacturing them relying on the current methods using toxic materials is highly harmful to our environment.

“Since typical QDs often involve toxic material, such as cadmium, lead, or other heavy metals, environmental concerns have been frequently deliberated when using nanomaterials. Our proposed process and fabrication method for QDs minimize these concerns,” said Ken-ichi Saitow, lead study author and a professor of chemistry at Hiroshima University. “Our proposed process and fabrication method for quantum dots minimizes these concerns.”

The application of porous silicon

Porous silicon (Si) has photoluminescence properties stemming from its microscopic (quantum-sized) dot structures that serve as semiconductors. It has a variety of applications: it is used in lithium-ion batteries, luminescent materials, biomedical sensors, and drug delivery systems. Since Si can be found abundantly in nature, its use would be essential to scale up to prevent the use of toxic materials instead. Using a non-toxic quality of silicon makes it a very attractive alternative. Rice husk, the byproduct of milling rice, is an excellent high-purity silica (SiO2) source.

“The team used a combination of milling, heat treatments, and chemical etching to process the rice husk silica: First, they milled rice husks and extracted silica (SiO2) powders by burning off organic compounds of milled rice husks. Second, they heated the resulting silica powder in an electric furnace to obtain Si powders via a reduction reaction. Third, the product was a purified Si powder that was further reduced to 3 nanometers in size by chemical etching. Finally, its surface was chemically functionalized for high chemical stability and high dispersivity in solvent, with 3 nm crystalline particles to produce the SiQDs that luminesce in the orange-red range with high luminescence efficiency of over 20%” – as explained in this article on the university’s webpage. “

The LEDs were assembled as a series of material layers. An indium-tin-oxide (ITO) glass substrate was the LED anode; it is a good conductor of electricity while sufficiently transparent for light emission. Additional layers were spin-coated onto the ITO glass, including the layer of SiQDs. The material was capped with an aluminum film cathode. The chemical synthesis method the team developed has allowed them to evaluate the optical and optoelectrical properties of the SiQD light-emitting diode, including the structures, synthesis yields, and properties of the SiO2 and Si powders and SiQDs.”

“By synthesizing high-yield SiQDs from rich husks and dispersing them in organic solvents, it is possible that one day these processes could be implemented on a large scale, like other high-yield chemical processes,” said Ken-ichi Saitow.

Spillover effects

What is immensely exciting about the study and news is that it potentially could be applied to other plants, including sugar cane, wheat, barley, and grasses. Hopefully, scaling up the methodology could quickly lead to the commercialization of this eco-friendly approach to creating luminescent devices.

The research team’s next steps include developing higher efficiency luminescence in the SiQDs and the LEDs. They will also explore the possibility of producing SiQD LEDs other than the orange-red color they have created in this research project.

More and more companies and industries work towards a sustainable future relying on material recycling during manufacturing processes, and such scientific discoveries significantly accelerate the process of adopting upcycling methodologies. Nowadays, concern for the environment is one of the maxims of big technology companies and scientists who work together on solutions that we have not even dreamt of until now.